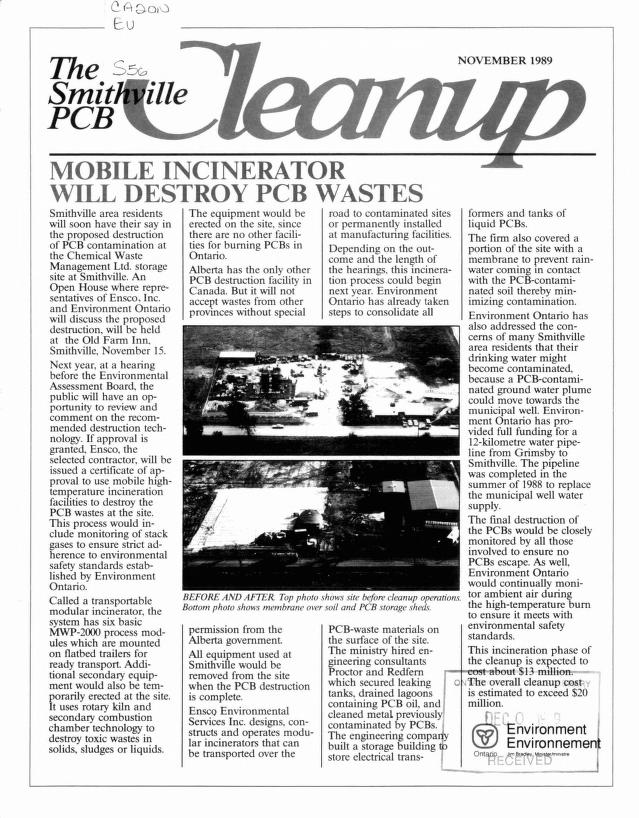

MOBILE INCINERATOR WILL DESTROY PCB WASTES

Smithville area residents will soon have their say in the proposed destruction of PCB contamination at the Chemical Waste Management Ltd.

LAG Technology's objective is to offer an immediate, safe, efficient, complete and economical solution to industries, governments and the military. LAG Technology's thermal chemical decomposition plant is able to safely handle hazardous waste materials contained in land and in current storage facility sites.

The savings of millions of dollars from the elimination of hazardous waste storage facilities helps to justify the safe destruction of these wastes, improve health and reduce long-term environmental risk.

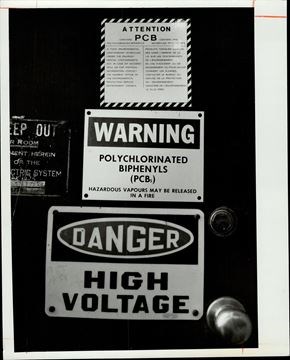

In 1985, the Provincial Government authorities discovered the major degradation of Polychlorinated Biphenyl (PCB) storage facility at Smithville, Ontario. PCB's stored at the facility were found to be leaching into the surrounding area. The highly contaminated PCB clean up by the Ontario Ministry of Environment and Energy at Smithville, Ontario utilized the government approved LAG-1000 technology to destroy 18,000 tonnes of PCB material including soils, shredded electrical equipment and liquids. The facility was in operation for a period of 18 months (early 1990’s).

For political reasons (during the Bob Ray NDP Administration) the Technology, once it had completed its mission, was ordered to return to the U.S. LAG Technology proposes to utilize this same proven technology to decontaminate many hazardous wastes streams including PCB's.

Help us raise the capital we need!

LAG Technology has Certificate of Approval for its unique technology from the Ministry of Environment (Ontario) and USEPA (9 Regions).

LAG Technology is readily suitable for electrical co-generation and steam delivery (heating and cooling).

LAG Technology has the ability to provide an immediate solution to the Toronto municipal waste disposal controversy.

LAG Technology Inc.’s competitive market advantages are highlighted as follows:

• owns an exclusive thermal oxidation technology that is able to handle a wide range of hazardous waste (from low level radioactive to high level PCB and Dioxin and Furons);

• technology fully licensed and approve by The Ministry of Environment (Ontario);

• technology fully licensed and approve by The U.S. Environmental Protection Agency (EPA);

• plans underway to construct and operate a MWP-2000 system on a currently Ministry approved ideal site in Canada (once sufficient Capital is raised)

• Technology currently operating in the U.S.A.

• no competition in Ontario (only Sensor, formerly Bovar in Alberta);

• technology is transportable;

• technology is well suited to handle municipal waste and hospital waste;

• technology is well suited to provide on-site soil remediation for a wide range of land contamination issues (brown fields);

• technology capable of steam delivery and electrical co-generation;

• Several international projects are being pursued (Mexico, Southern U.S. (Katrina/Wilma related), China and Barbados);

This method introduced solvents which were hazardous and added a source of further contamination, this method was expensive, incomplete and no longer an alternative.

The disposing of wastes in landfill sites is no longer an alternative since the regulations set out a maximum of 50 parts per million (ppm), by weight of PCBs is the general release prohibition.

This method is limited to waste that will produce acceptable asphalt. New requirements for air pollution equipment have caused most cement companies to withdraw from the market.

Reduces contamination by allowing bacteria to consume hydrocarbon contaminant. This method is limited to contamination levels below 15,000 ppm.

Consists of oxidizing waste material in an incinerator. This method has emerged as the technology of choice for destruction of contaminating waste.

Medical waste material dissolved in the incinerator. This method has emerged as the technology of choice for destruction of medical contaminated waste.

Smithville area residents will soon have their say in the proposed destruction of PCB contamination at the Chemical Waste Management Ltd.

When PCB contamination was discovered in the lagoon area in 1985, the Ontario Ministry of the Environment (MOE) began a site decommissioning and remediation program....

About 430,000 litres of toxins were stored at the site between 1978 and 1985. About half was polychlorinated biphenyl-laden oil used at one time to...

West Lincoln council wants the province to keep local businesses informed of any changes in the area affected by PCB contamination should new and more refined research determine...